Install a Tesla Model S or Model X

"P" (P90D, P100D) Large Drive Unit (LDU) in any vehicle and achieve

complete control with AEM EV’s LDU Inverter Control Board (ICB, PN 30-8402) and

VCU200 Vehicle Control Unit (PN 30-8000)! This system provides full control of

the LDU for programming torque curves, torque limits, regenerative braking,

accelerator pedal response, drive-mode switches, and much more. The Tesla LDU

currently comes in two versions, Base and Sport.

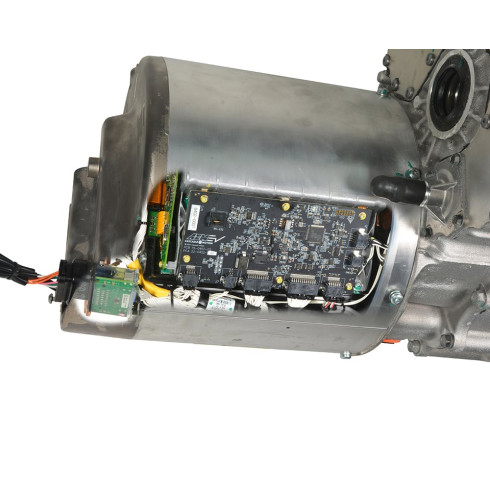

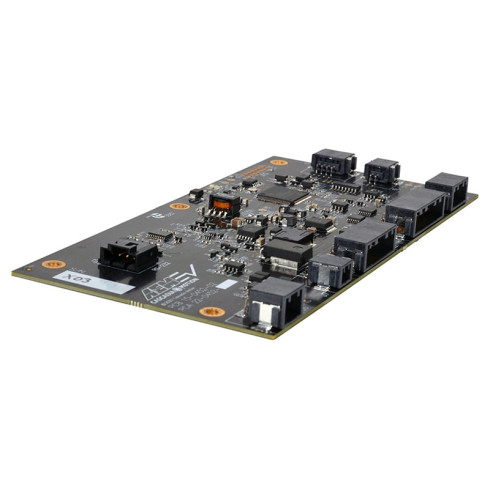

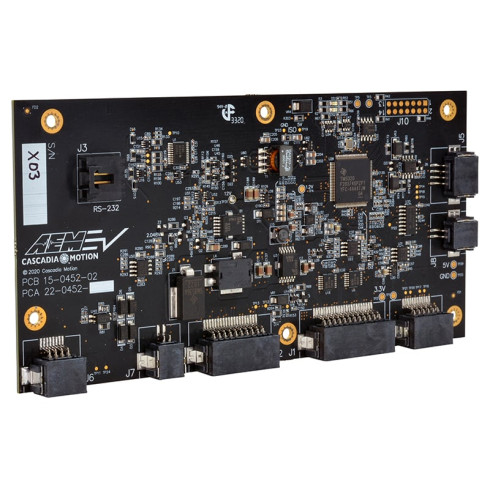

AEM EV’s Tesla Inverter Control Board acts as

a VCU expansion device that replaces the stock Tesla ICB. Once connected to a

VCU200 using the supplied communications harness, calibrators can program

propulsion strategies and characterize inputs through the VCU using AEMcal

software. AEM EV’s LDU ICB was co-developed with Cascadia Motion, an industry

leader in EV propulsion systems, to ensure the highest standards of quality and

reliability.

NOTE: The Inverter Control Board must be used

with a VCU200 Vehicle Control Unit for programming and controlling a Tesla LDU.

This system is designed for conversion and motorsports vehicles with Tesla LDU

swaps. It will not control a Tesla LDU in a Tesla OE chassis

.

Improved Performance Over Stock

AEM EV’s engineers were able to increase the

peak torque output of the Base LDU using the AEM EV LDU controls system. The

following dyno chart shows a +50Nm torque increase with the AEM EV VCU &

Tesla LDU ICB over the stock torque level.

TEST 1: The green trace is a Base LDU with OE

Tesla control board used with a competitor CAN spoofer control device. The red

trace is the same Base LDU with AEM EV controls package. Average peak torque

from the OE control board is 415Nm and average peak torque from AEM EV controls

package is 465Nm – a +50Nm gain! Both tests were completed at the same HV

voltage level using AEM EV’s stationary dyno power supply.

It's important to note that the motor’s

maximum achievable power output is highly dependent upon the HV battery’s

discharge characteristics. Certain battery cell types and battery pack

configurations will lend themselves to making more overall power. Because of

this, AEM is not able to guarantee a specific power output, however, the peak

torque output should almost always be achievable. Ultimately, since power

directly correlates to torque and rpm, peak power will always be based on how

long the motor’s peak torque can be made which is directly related to the

battery’s discharge power capability.

A comparison that highlights this point can be

seen in the following dyno chart the shows the different power levels that can

be achieved with a Base LDU depending on battery discharge characteristics.

TEST 2: The blue trace is a Base model 2013

Model S P85 with Base LDU and stock 85kWh battery pack. The green trace is the

AEM EV R&D development car, the “TesTang”, a 2007 Ford Mustang GT with Base

LDU swap and hybrid minivan batteries. The red trace is the AEM EV R&D dyno

test rig with Base LDU and stationary dyno power supply (130kWh energy

capacity, 1700Amp DC discharge rating). The +50Nm torque gain is realized with

the AEM EV controls package over stock but it’s important to note that how long

the motor’s maximum torque output can be sustained will determine the ultimate

power level. For instance, with the lower torque output and limited battery

discharge capability, the stock Model S is only capable of making ~250kW of

power. The AEM EV TesTang with increased torque output and high-power hybrid

batteries can sustain a significantly boosted torque curve that results in more

power – 300kW peak giving a +50kw performance advantage over a stock Base Model

S 85. A more extreme example of this is with the very large, very powerful

stationary battery/power supply used by AEM EV for motor/inverter development.

With 1700Amps of DC discharge capability and minimal voltage sag, the Base

LDU’s torque curve is further boosted and results in a peak power output of

nearly 350kW! Although it may be difficult to physically house a battery of

this size in a road vehicle, this represents the possibility of realizing a

+100kW power increase over a stock Model S with a Base LDU!

Other improved performance aspects include the

elimination of any hard-coded motor speed limiters as well as HV battery

voltage limits*. Through testing, it was observed that the stock Tesla LDU

controls will limit motor speed to 14,500-15,200 rpm. The AEM EV controls

package completely removes this limitation and allows motor speeds up to the

max advised mechanical motor speed of 18,000 rpm allowing for higher ultimate

vehicle speeds. It has additionally been observed that the stock Tesla LDU

controls limit allowed maximum battery voltage to 404 volts. HV battery supply

voltage will directly impact the motor’s ultimate power output and allowing for

a higher supply voltage will result in more power. The AEM EV Tesla LDU ICB has

no hard-coded voltage limit, but the inverter’s 450-volt DC link capacitor

rating should always be observed.

* The ability to apply higher

RPM and voltage to increase a Tesla Drive Unit’s power may result in

degradation of the unit.

Comprehensive Control Through a

Central Interface

AEM EV’s optional CAN expansion modules can

provide additional data channels, our CAN-based modular battery management

system integrates seamlessly with any AEM EV VCU-controlled vehicle, our

CAN-based PDU-8 Power Distribution Units provide accessory control over

switched functions, and data visualization/logging of any and all channels from

devices on any connected CAN network is possible using AEM EV’s CD Carbon

logging dash displays. All programming for our BMS and PDU-8 modules is

performed in AEMcal software for the VCU200 and VCU300.

Intuitive Software

AEMcal software for AEM EV VCUs simplifies the

process of customizing the power delivery strategies and controlling all the

ancillary subsystems of EV motorsports and conversion vehicles. AEMcal software

is free to download, and it is fully enabled (not a demo version), allowing

users to explore its full suite of features and capabilities.

Utilizing a simplified

and intuitive graphical interface that combines tables and graphs for

implementing strategies for torque delivery, launch control (stationary and

dynamic), traction control, regenerative braking, speed limiting, map switching

and more, AEMcal software puts an end to the need for stacking multiple

controllers to control an EV's propulsion and ancillary systems. AEMcal

software is available for download on the Software page.

- Stock: In Stock

- Model: 30-8402

- Weight: 1.40lb

- SKU: 30-8402

- UPC: 840879027179

%20Control%20Board/0449a3b8df2fb598e09dd83ad91a067955b3c7bc-190x190w.jpg)

%20Control%20Board/f68202fc36db25c9dcec801391c0f456cb757423-190x190w.jpg)